5TV - Poppet Style Hydraulic Couplings

Beginning in 1968, Hydraulics Inc. has produced the 5TV series coupling for service in extremely rugged constant duty high-horsepower fluid power systems. Today, world wide, virtually every manufacturing segment finds use for this dependable coupling in equipment for construction, natural resource gathering, transportation, material handling and many others. Standard coupling sizes are 3/4″ through 3″ bore size.

The Hydraulics Inc. 5TV series thread to connect coupling presented here consists of two valved halves retained in sealed connection by stub-acme threads. Connection is by winged thread nut rotated manually to overcome valve springs and any fluid pressure behind the valves. Valves are full open when threads are totally engaged. Valves become full closed before threads become totally disengaged.

Showing 1–4 of 51 results

Product Filters

-

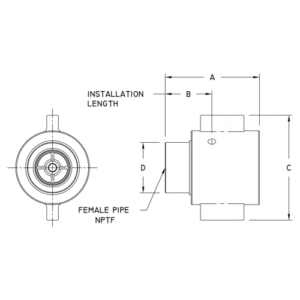

5TV-C-12

Port Connector: PF - Female Pipe Port Size: -12 (3/4") Kit/Product Type: 5TV Coupling -

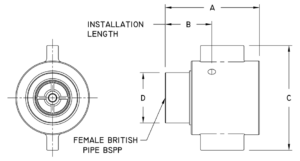

5TV-C-12BF

Port Connector: BF - Female British Pipe Port Size: -12 (3/4") Kit/Product Type: 5TV Coupling -

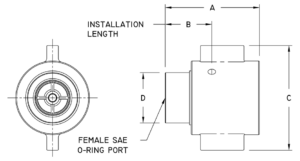

5TV-C-12OF

Port Connector: OF - Female SAE O-Ring Port Size: -12 (3/4") Kit/Product Type: 5TV Coupling -

5TV-C-16

Port Connector: PF - Female Pipe Port Size: -16 (1") Kit/Product Type: 5TV Coupling

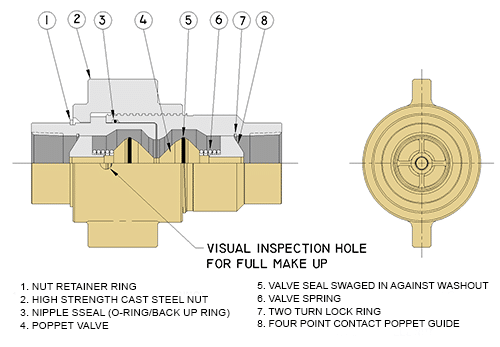

Product Diagram for 5TV - Poppet Style Couplings

Labeled Diagram for our 5TV - Poppet Style Couplings

Design Features of Our 5TV Poppet Style Couplings

- Excellent flow characteristics for continuous duty applications. View Flow Data

- High strength steel poppet guides prevent break up and washout of coupling valves during high surge and shock conditions

- Hammer lug wing nut aides in assembly of coupling under pressure

- Full assembly can be visually verified at coupler nut inspection hole

- Flat crested stub-acme threads and all steel construction withstand storage and rig-up damage

- Protective treatment of zinc plating with yellow chromate RoHS compliant finish

- Various port options available, Female NPTF, Female SAE O-Ring Port, Female BSPP

Generally stated, these couplings simplify the rigging of long length, large bore flex hose assemblies. They are designed to operating in rugged environments under extreme pressures as well as structural and system induced surges and shockloads. Valve construction permits assembly against pressure created by thermal expansion of fluid in the hose bore and make up is facilitated by a high strength hammer lug nut.

Operating Limits for 5TV Poppet Style Couplings

- 5,000 P.S.I. (34.5 Mpa) Some thread port options are de-rated.

- Full 4:1 Safety Factor – all sizes

- Vacuum to 28″ Hg (1.0 bar)

- Temperature range -30°F to +250°F (-34°C to +121°C) – Standard Buna Seals

- Protective Treatment – Zinc Plating with Yellow Chromate RoHS Compliant Finish

- Sizes – 3/4″ thru 3″