Hydraulics Inc. E15TV Couplings were specifically designed for use in transfer of refrigerant from transport to storage vessels. CAUTION! User must assure compatability of coupling body and seal materials with fluid. Consult fluid manufacturer to determine compatibility.

A key safety feature of this hand assembled coupling is that during Coupler and Nipple disconnect, the shut off valves close before the assembly seal vents. Virtually no fluid spill occurs. Should a valve not seal the two halves can be re-connected.

The Caps and Plugs including retention chains and rings are designed to limit Coupler and Nipple contamination and they provide safety features. Also the Coupling halves can be arranged on fluid lines to prevent liquid and vapor line crossover errors at transfer hook up.

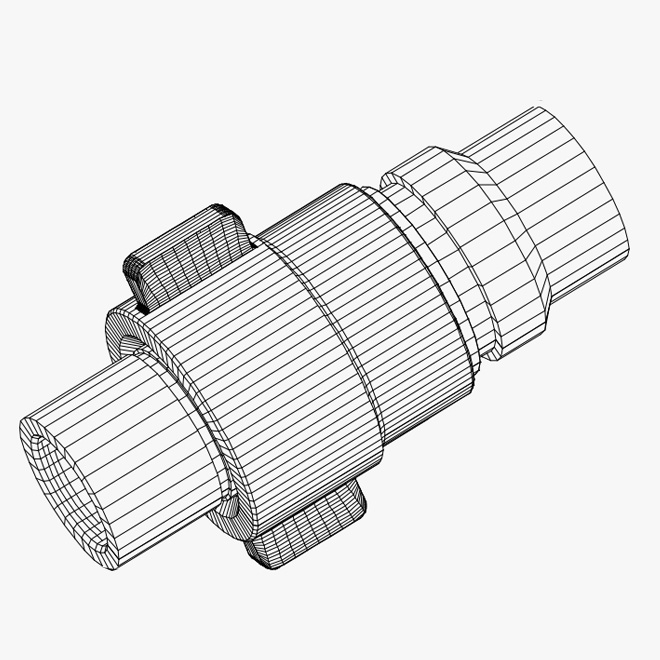

Coupling Assembly

When fully inserted, the Coupler Pressure Relief Plug is designed to open the Coupler valve and communicate refrigerant trapped in the transfer hose bore. Thermal induced pressure build-up is then controlled by the plugs 400 psi relief valve. The plug also guards against contaminants and a button exhaust valve allows trapped gas release before plug removal.

Coupler Pressure Relief Plug

The Coupler Safety Plug is optional to the Relief Plug. It guards against contaminants and is designed to prevent product loss should the coupler valve fail. The safety plug button exhaust valve allows release of trapped gas before plug removal.

Coupler Safety Plug

The Nipple Safety Cap is a contaminant safeguard and is designed to prevent product loss should the nipple valve fail. The cap’s button exhaust valve allows release of trapped gas before removing the cap.

Related Documents & Downloads